Driven by the demand for high power density and extended range, new energy vehicles (NEVs) require increasingly advanced standards for thermal management and insulation protection. For critical components such as battery modules, electronic control units, and motor drivers, we offer a comprehensive range of thermal and insulation material solutions that help our customers achieve design goals of system stability, cooling efficiency, and structural safety.

Our solutions include thermal pads, potting compounds, thermal adhesives, and insulation pads—all featuring excellent thermal conductivity (1.5 to 5 W/m·K) and high dielectric strength. These materials effectively reduce system thermal resistance, enhance heat transfer efficiency, and ensure insulation and protection performance under harsh environmental conditions.

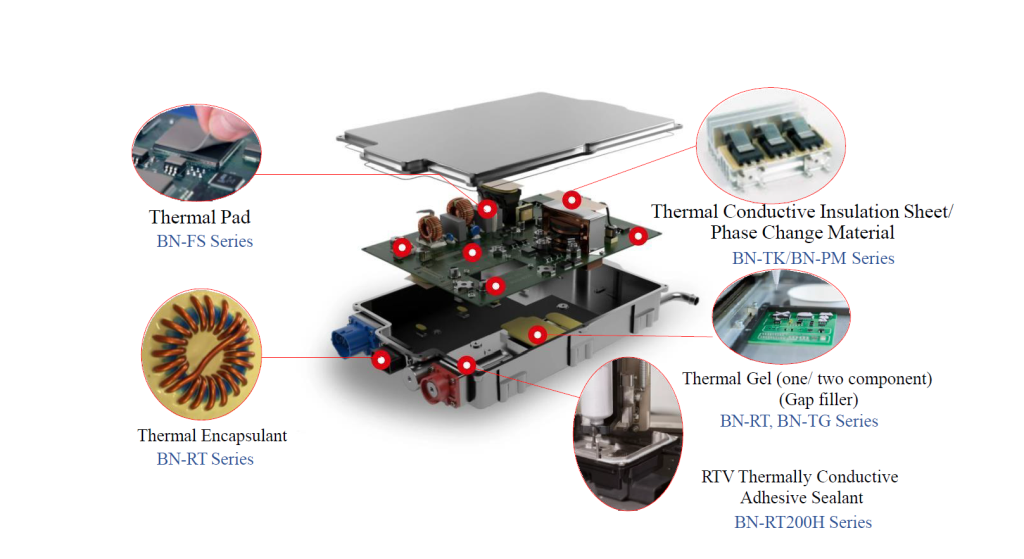

Thermal and Insulation Material Applications in On-Board Charger (OBC) Modules

As one of the core power conversion components in electric vehicles, the on-board charger (OBC) features high-density and high-efficiency circuit designs that demand advanced thermal management and insulation protection.

To meet the dual requirements of stability and reliability for critical components, we offer a wide range of thermal and insulation material solutions—including thermal silicone pads, potting compounds, thermal adhesives, phase change materials (PCMs), and thermal insulation sheets. These materials help customers enhance system heat dissipation, reduce thermal resistance, and mitigate operational risks.

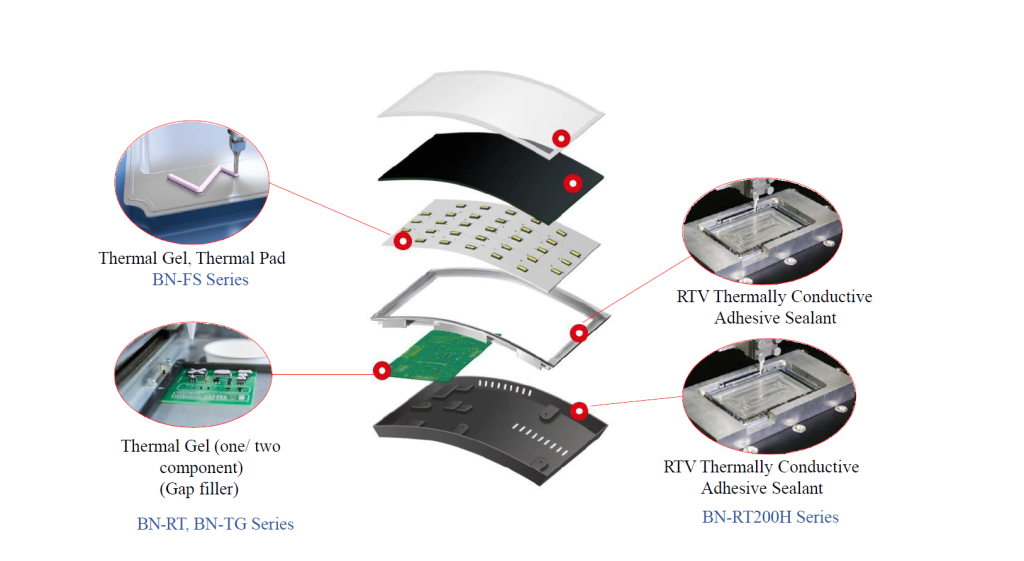

Thermal Sealing and Gap-Filling Solutions for ADAS Display Modules

Advanced Driver Assistance System (ADAS) display modules must withstand prolonged high-brightness operation along with the heat and vibration challenges of in-vehicle environments. To ensure structural stability and efficient thermal dissipation, high-performance thermal interface and sealing materials are essential.

We offer a complete range of thermal solutions for ADAS display modules, including thermal pads, one- and two-component gap fillers, and RTV thermal adhesives. These materials effectively fill gaps between components such as LEDs, PCBs, and light guides, significantly reducing thermal resistance and improving heat dissipation efficiency. Additionally, they provide excellent structural integrity and environmental protection, extending module lifespan and enhancing in-vehicle reliability.